No tracking number?

Definition:

The flat-bottom hole (FBH) is machined to have a flat reflecting surface at the hole bottom. Flat bottom holes are similar to counter bores but do not include a center drill. These holes are designed to drill flat bottom blind holes for European-style hinges, etc. Flat bottom boring bits are also used for drilling large diameter thru-holes without the plug that is typical when using a hole saw.

Definition:

The side-drilled hole (SDH) is typically a drilled hole, the side wall of which is used as the reflecting surface. Unlike the FBH, the bottom of a SDH serves no purpose. SDHs are often reamed after initial drilling. SDHs are often drilled in pipe walls at specified locations from the diameter, e.g.: 1/4T, 1/2T, and 3/4T. They can be drilled either longitudinally or circumferentially to the axis of the pipe. They can also be machined in plate, bar or other products. Primary use is Ultrasonic testing. Available in diameters from .010".

Definition:

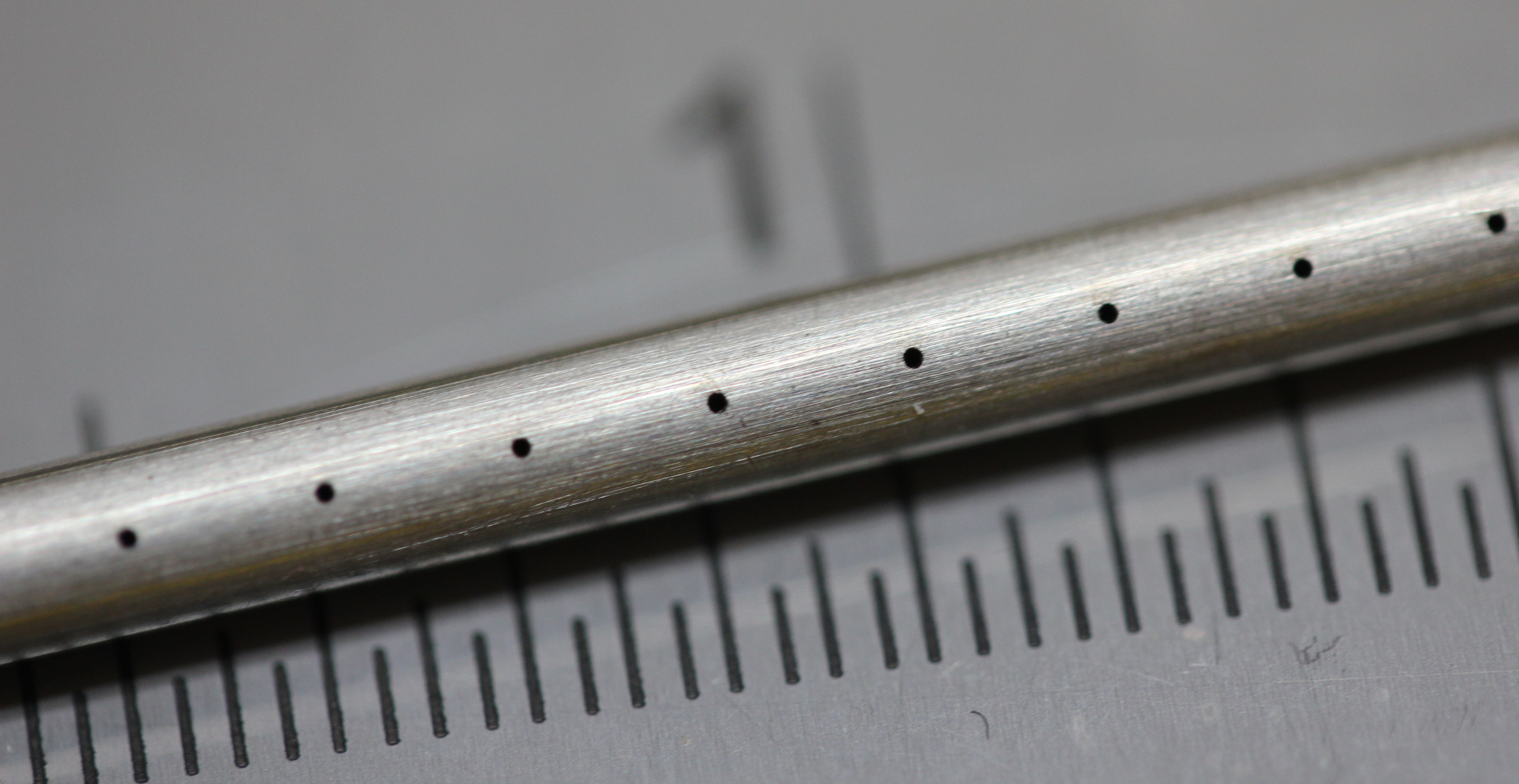

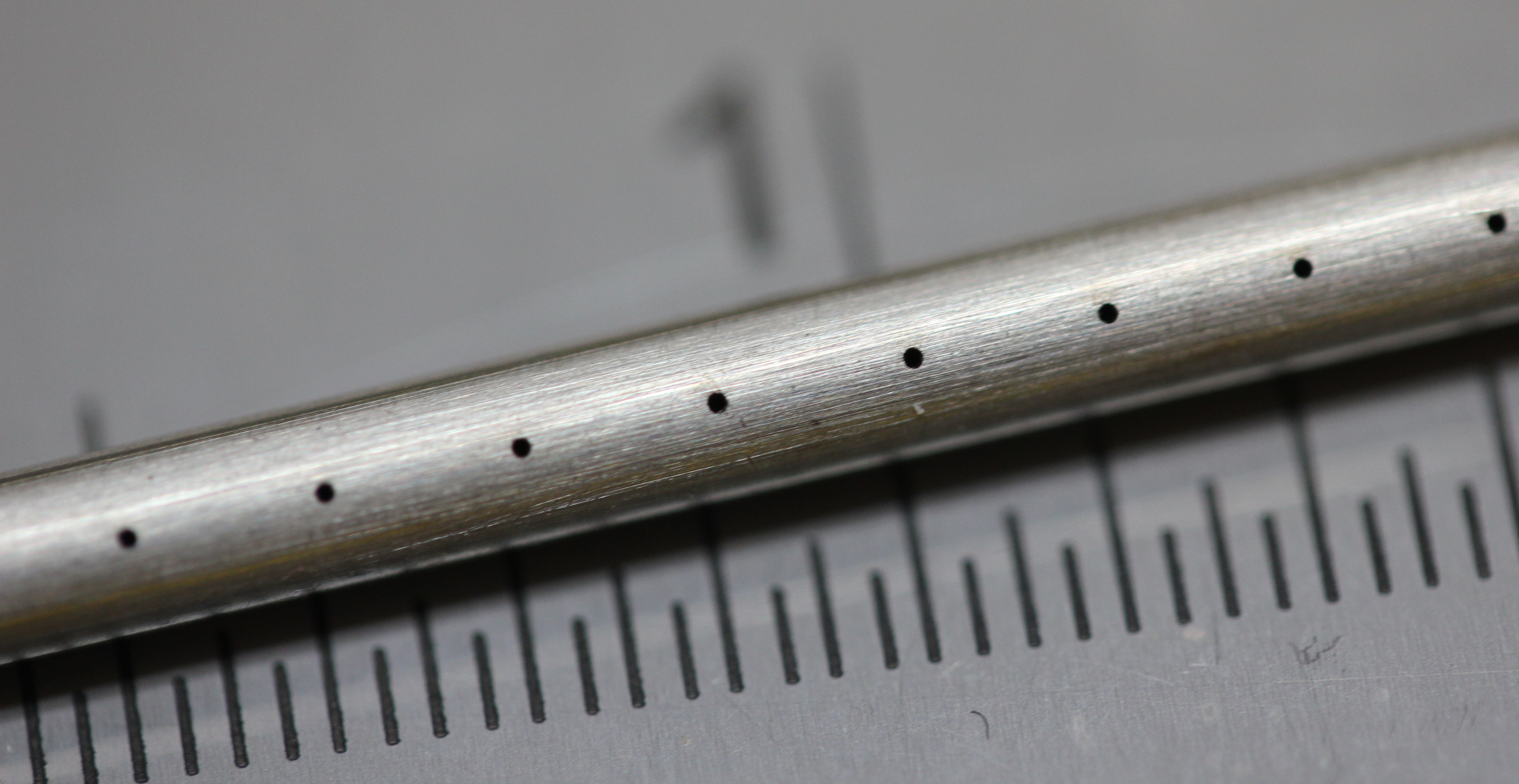

The micro-sized hole (MSH) is a small diameter hole used primarily in Liquid Penetrant inspection. Hole diameter is normally 0.004 to 0.005", and hole depth is 0.008 to 0.010". These micro-sized holes meet the requirements of the U.S. Navy's NSTR-99 Rev. 2 (Qualification Examination Requirements for Nondestructive Test Personnel). They can be machined in welded plate, pipe, bolts, or any test prop. Also available in diameters and depths other than stated above.

Definition:

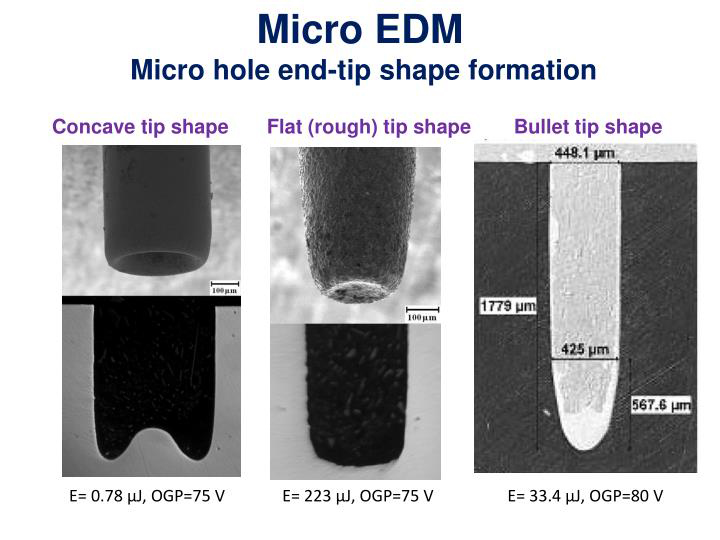

The concave radius-bottom hole is machined with a concave radius at the hole bottom. Applications include ID pitting of tube or pipe for Eddy Current Inspection; and Liquid Penetrant test props. Available in diameters from 0.004".

Definition:

The convex radius-bottom hole is machined with a convex radius at the hole bottom. Available in diameters from 0.030".

Definition:

These holes and pits are machined in irregular configurations, not described above. Includes star-shaped, square holes, hex holes, and realistic pits. EDM pit electrodes can be cast from real pits and used to reproduce actual pits very accurately.

Definition:

The flat-bottom hole (FBH) is machined to have a flat reflecting surface at the hole bottom. Flat bottom holes are similar to counter bores but do not include a center drill. These holes are designed to drill flat bottom blind holes for European-style hinges, etc. Flat bottom boring bits are also used for drilling large diameter thru-holes without the plug that is typical when using a hole saw.

Definition:

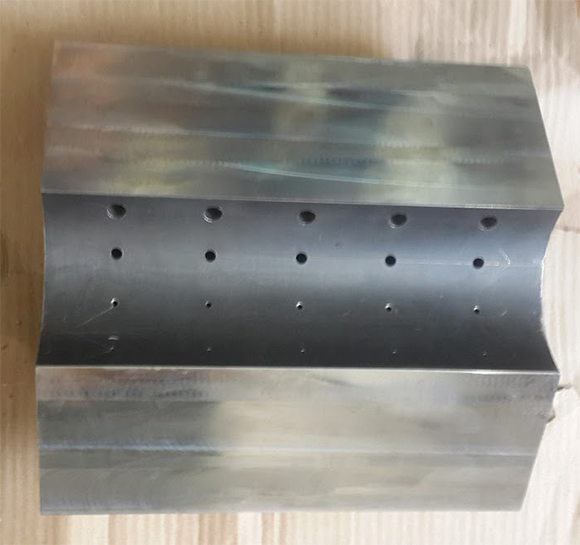

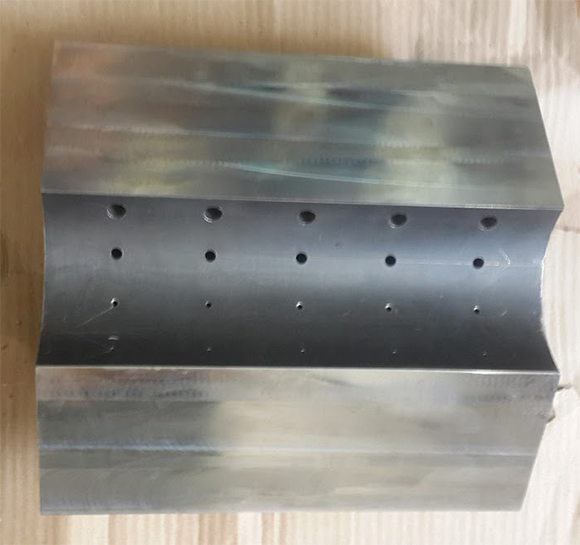

The side-drilled hole (SDH) is typically a drilled hole, the side wall of which is used as the reflecting surface. Unlike the FBH, the bottom of a SDH serves no purpose. SDHs are often reamed after initial drilling. SDHs are often drilled in pipe walls at specified locations from the diameter, e.g.: 1/4T, 1/2T, and 3/4T. They can be drilled either longitudinally or circumferentially to the axis of the pipe. They can also be machined in plate, bar or other products. Primary use is Ultrasonic testing. Available in diameters from .010".

Definition:

The micro-sized hole (MSH) is a small diameter hole used primarily in Liquid Penetrant inspection. Hole diameter is normally 0.004 to 0.005", and hole depth is 0.008 to 0.010". These micro-sized holes meet the requirements of the U.S. Navy's NSTR-99 Rev. 2 (Qualification Examination Requirements for Nondestructive Test Personnel). They can be machined in welded plate, pipe, bolts, or any test prop. Also available in diameters and depths other than stated above.

Definition:

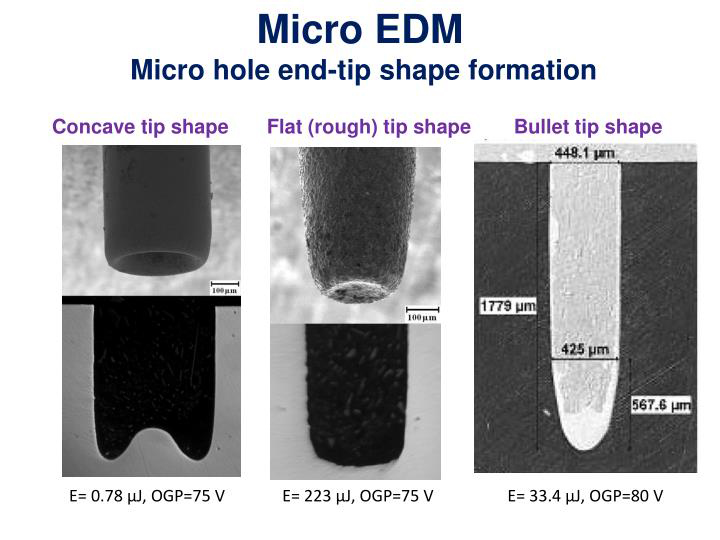

The concave radius-bottom hole is machined with a concave radius at the hole bottom. Applications include ID pitting of tube or pipe for Eddy Current Inspection; and Liquid Penetrant test props. Available in diameters from 0.004".

Definition:

The convex radius-bottom hole is machined with a convex radius at the hole bottom. Available in diameters from 0.030".

Definition:

These holes and pits are machined in irregular configurations, not described above. Includes star-shaped, square holes, hex holes, and realistic pits. EDM pit electrodes can be cast from real pits and used to reproduce actual pits very accurately.

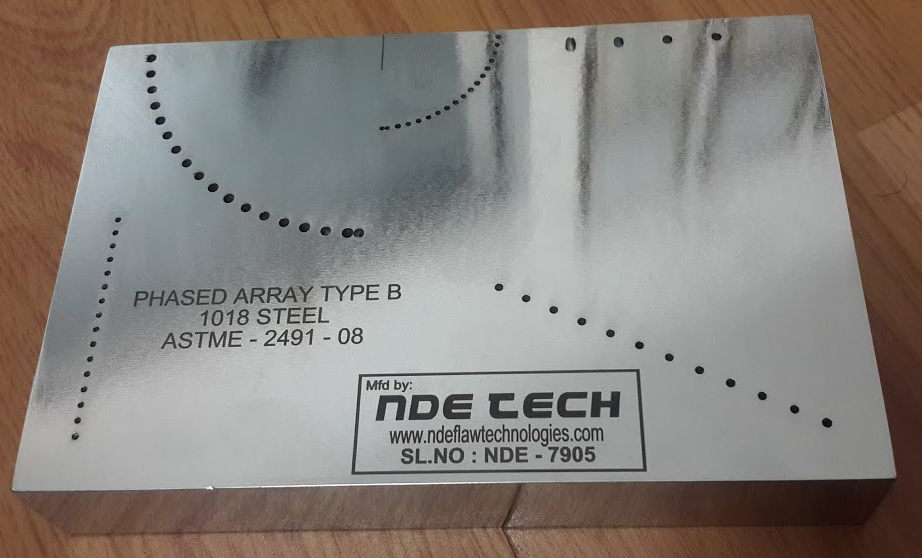

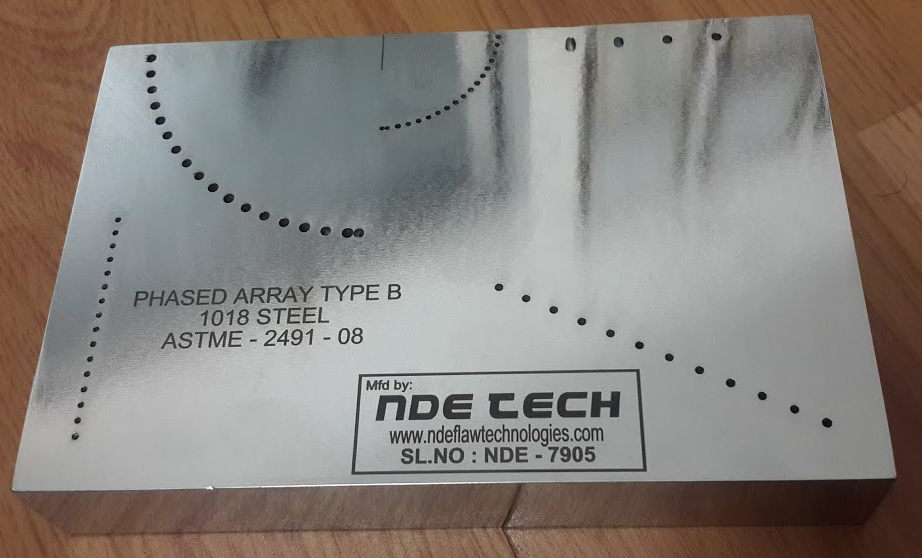

NdeTech was established in 2012 as NDT based company. Our portfolio spans across industrial services and manufacturing sectors. NdeTech was established as an NDT& NDE Reference Standards and flawed weld specimens manufacturing company, and NDT Training Certification, Recruitment Consultant for Inspection Industries provider to cater to the requirements of various industries in India as well as abroad..

2024 NDETECH All Right Reserved.