No tracking number?

A large list of tubing as per ASME standards are available. Also, we can develop customized solutions that meet the specific needs of our customers. Whether you need tube supports, uncommon flaws or specialized packaging for the standards, NDE can support.

Our experience in dealing with all simulated flaws from EDM notches to thinning and expansions puts us in a unique position to recommend procedures and implement standards that increase your probability of detection during the inspection of plants worldwide.

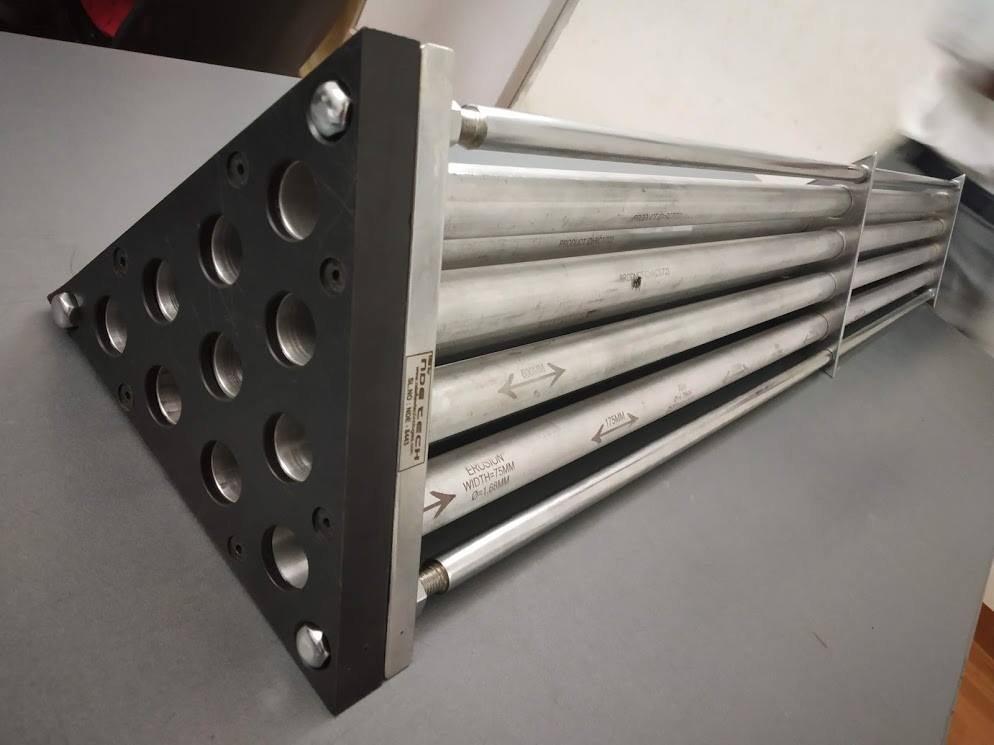

We specialize in custom eddy current tubes

Eddy Current Tube Standards. Ready to request a quote for a standard?

What is the material? (Alloy, OD, and Wall)

Is there any specification, the standard needs to comply with? (ASME, etc.)

And have years of experience in machining a huge range of defects. From TWHs and FBHs, OD and ID grooves, milled flats, and OD and ID thinning bands, to ID FBHs, RBHs, ID contoured flats, 120째/180째 wear scars, tapered flaws, and tube-to-tube wear,

In eddy current testing, the use of reference standards in setting up the equipment is particularly important since signals are affected by many different variables and slight changes in equipment setup can drastically alter the appearance of a signal. As with most other NDT methods, the most useful information is obtained when comparing the results from an unknown object to results from a similar object with well-characterized features and defects. In almost all cases, eddy's current inspection procedures require the equipment to be configured using reference standards.

For crack detection, corrosion thinning, and other material damage, reference standards are used to set up the equipment to produce a recognizable signal or set of signals from a defect or set of defects. In many cases, the appearance of a test signal can be related to the appearance of a signal from a known defect on the reference standard to estimate the size of a defect in the test component. Signals that vary significantly from the responses produced by the reference standard must be further investigated to determine the source of the signal.

The reference standard should be of the same material as the test article. If this is not possible or practical, it should be of a material that has the same electrical conductivity and magnetic permeability. Component features (material thickness, geometry, etc.) should be the same in the reference standard as those in the test region of interest. If the reference standard is the type with intentional defects, these defects should be as representative of actual defects in the test component as possible. The closer the reference standard is to the actual test component, the better. However, since cracks and corrosion damage are often difficult and costly to produce, artificial defects are commonly used. Narrow notches produced with electron discharge machining (EDM) and saw cuts are commonly used to represent cracks, and drilled holes are often used to simulate corrosion pitting.

Common eddy current reference standards include:

Conductivity standards

Flat plate discontinuity standards.

Flat plate metal thinning standards (step or tapered wedges).

Tube discontinuity standards.

Tube metal thinning standards.

Hole (with and without fastener) discontinuity standards.

NdeTech was established in 2012 as NDT based company. Our portfolio spans across industrial services and manufacturing sectors. NdeTech was established as an NDT& NDE Reference Standards and flawed weld specimens manufacturing company, and NDT Training Certification, Recruitment Consultant for Inspection Industries provider to cater to the requirements of various industries in India as well as abroad..

2024 NDETECH All Right Reserved.